Exergy Analysis of Kalina Cycle System (KCS) 34 with Mass Fraction Ammonia–Water Mixture Variation

Nasruddin1, Maulana Rifaldi1, Agus Noor1, Rama Usvika2

1Department of Mechanical Engineering, Engineering Faculty, University of Indonesia

2PT. Rekayasa Industri, Jakarta, Indonesia

1. Introduction

In order to solve the problem of primary energy consumption in the energy systems and to reduce environmental pollution, new thermodynamic cycles have been investigated and developed during the past 20 years [1].

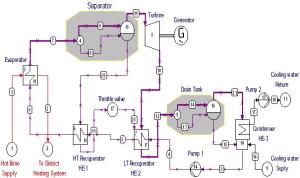

Kalina Cycle® System 34 (KCS 34) was designed by Dr. Alexander Kalina specifically for generating electricity using low to medium temperature geothermal resources as a “topping” energy conversion prior to district heating. A flow diagram of KCS 34 is shown in Fig. 1. Basic flow parameters are shown on this diagram.

For applying a novel cycle a comprehensive view in thermodynamic is important, thermodynamic system is influence by surrounding environment such as pressure and temperature. This research is made for a study in Kalina cycle system that has been applied in Husavic, Iceland and the final conclusion is a validation model and the appropriate condition of working fluid composition that have improved efficiencies of thermal power production

1. Methods

2.1.Cycle description

The diagram below shows the Kalina Cycle for geothermal power plant, the hot water or brine water enters the evaporator and the heat is transferred to ammonia-water. And the ammonia water goes into turbine and the turbine generates the generator to produce electricity [3].

Fig 1. Kalina Cycle

2.2.Exergy analysis method

”]![control volume Fig. 2. A control volume which exchanges energy by heat transfer Q, at surface temperature Tj [4]](https://maulcaem.wordpress.com/wp-content/uploads/2009/05/control-volume.jpg?w=300&h=197)

The thermomechanical exergy associated with the state of a system is measured by the maximum reversible work that could be delivered by the system as it proceeds toward a state of equilibrium with the environment while any heat transfer occurs solely with the environment. This state of equilibrium is its dead state at T0 and P0, and the standard atmosphere or environment is recommended to be 298.15 K and 1.01325 bar (1 atm) [5]

under the same circumstances the irreversibility is

The total exergy of the system becomes the summation op physical exergy and chemical exergy

The physical exergy component calculated using the following relation:

The physical exergy component calculated using the following relation:

The calculation procedure for the chemical exergy of various substances based on the standard chemical exergy values of respective species is widely discusses by Bejan et al., Ahrendts, and Szargut et al. for the ammonia-water fluids to be considered, the chemical exergy of the flow is calculated using the following relation:

Which the standard chemical exergy of ammonia and water, respectively, and their values are taken from ahrendts[6]

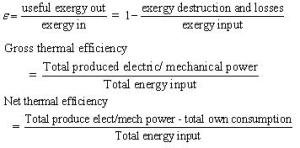

First and second-law efficiencies are different in one other important respect. The first law is a conservation principle. On the other hand, entropy and exergy from a second-law viewpoint are non conserved properties. In the presence of irreversibilities, entropy is produced and exergy is destroyed. The former effect is measured by the entropy production , and the latter effect is measured by the irreversibility . Hence second-law efficiencies measure losses in exergy during a process. A general definition of a second-law effectiveness is

Total produced electric/mechanical power is Pgenerator or power from generator, Total own consumption is amount of energy use to run the plant auxiliaries, such as: the pump or total Ppump and Total energy input is total heat absorbed to evaporator.

2.1.Simulation and description

The schemes of Kalina cycle were built using cycle-tempo5.0, figure 3. For the input data were the factual data from Húsavík. No. 1 and 2 for the hot brine supply trough evaporator as a boiler transferring the heat to ammonia-water, ammonia-water is the pipe in close system and no. 9 and 11 for cooling water.

Fig. 3. KCS 34 scheme model

The input and parameters were made similar to the condition in Húsavík.

1. Results and discussion

3.1. Model validation

The cycle validation in calculating the data as the result shall similar or equal to factual output in the real Kalina power plant, the thermodynamic model was developed using Cycle Tempo in order to validate the reference took from geothermal power plant in husavic, Iceland.

Table 1. Validation

From all references that show at table, Cycle-Tempo has calculated all input data. The result of generated electric power or gross electric power has a close accurate power which is has error around 0.46% or has difference power about 0.09 kW from the references. Therefore, the scheme and all input for each apparatus in the scheme could be concluded that could be use for further analysis.

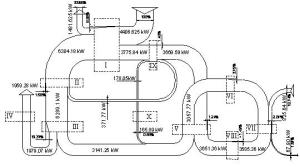

3.1. Exergy Flow

The exergy calculation result below, is the Kalina cycle system model, see fig. 3. The exergy flow in the system influenced by environment, apparatus efficiencies, etc.

fig. 4. diagram grassman, exergy flow in KCS 34

The Grassman diagram above show the exergy flow in the KCS 34 in the optimum condition. Apparatus denoted in Rome number, number I is Evaporator 1, number II is separator, number III is a turbine, number IV is generator, number V is LT Recuperator, number VI is drain tank, number VII is condenser, number VIII is a pump, number IX is a HT recuperator, all the unit is in kW. The losses in heat exchanging equipment such as apparatus number I, II, V, VII and IX are caused by pressure drop and other irreversibilities occurred. Turbine has the highest losses is because the turbine has a mechanical efficiency to the shaft rotation and manufacture.

By this condition the Kalina cycle would be analyze to get optimal performance by configuring the ammonia-water mass fraction and also by choosing a high efficiency apparatuses.

3.1. KCS 34 application in Indonesia

For applying KCS type 34 in Indonesia, there is a different condition to environment such as pressure and temperature for the dead state condition.

Geothermal site in Iceland has a different environment and climatic condition with Indonesia. In Indonesia, geothermal resources in normally located in the mountainous area, several hundred or thousands metres above sea level. However, the climatic condition in Indonesia is not as cold as Iceland. Typical air temperature at Indonesian Geothermal Site is around 18-24 oC. The cooling water source is normally taken from nearby river, with river water having average temperature around 22-24 oC. Meanwhile the cooling water supply temperature in Iceland is about 5oC. Hence, some thermodynamic parameters should be change in order to obtain the maximum electric power and efficiency using KCS-34.

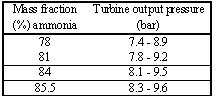

Kalina cycle system 34 was then modified in several parameters to find the optimum power output. To obtain the optimum power output, ammonia-water composition is considered as the most influenting parameters, so it will be varied starting from 78% up to 85.5% mass fraction, and each mass fraction act as constraint, therefore the outlet pressure from turbine has lower and upper limit, here is the result :

Table 2. constraint ranges

Fig. 5. power output generate on the system

The highest electric power produced can be achieved at 78% ammonia-water mass fraction and 7.4 bar outlet pressure, which can produced around 2.145 MW. Refer to fig.5, by increasing the electric power output and lowering the outlet pressure, the efficiency will increase and so does the exergy efficiency.

Table 3. efficiency

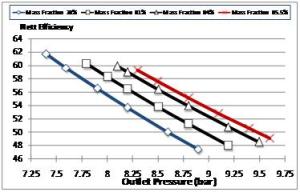

From each mass fraction, the graph below show us that increasing the outlet pressure from turbine will decreasing exergy efficiency because of the exergy absorb by the system from heat source is constant meanwhile the increasing of outlet pressure will lead to decreasing electrical power as useful work.

Fig. 8. exergy efficiency system

The net exergy efficiency:

For mass fraction 85.5% the highest exergy efficiency ηII = 69.00016%, For mass fraction 84% the highest exergy efficiency ηII = 68.62393%, For mass fraction 81% the highest exergy efficiency ηII = 67.06067%, For mass fraction 78% the highest exergy efficiency ηII = 66.88385%, and in a series the pressure are 8.3 bar ; 8.1 bar ; 7.8 bar ; and 7.4 bar, those are bottom line each mass fraction respectively.

This analysis refer to study Kalina cycle system type 34 application in Indonesia, the important things are how to choose the mass fraction and outlet pressure from turbine that maximize electric power output and also system efficiency.

4. Conclusions

- KCS-34 simulation model using Cycle Tempo has been proved to be a validate model for real installation in Husavic, Iceland. The model has produced calculated electrical output of 1.959 MW, which is very close to real condition in Husavic Site which currently produces electrical power output of 1.950 MW.

- If the outlet pressure from turbine is constant, by increasing the mass fraction of ammonia, the electrical power output will increase and so does the system efficiency. If the mass fraction is constant, by decreasing exit pressure from turbine, it will increase the electrical power output and the system efficiency.

- The highest electrical power output for KCS-34, if it is applied in Indonesia, shall be achievable using 78% mass fraction of ammonia-water and 7.4 bar exit pressure from turbine.

A final version of this transcript is available at Springerlink, British Library Direct, and JMST (Journal of Mechanical Science and Technology)

References

[1] Vidal, A., et al. (2006), Analysis of a combined power and refrigeration cycle by exergy method. Energy, vol. 31, pp.3401-3414

[2] P. Valdimarsson and R. Maack (2002). Operating experience with Kalina power plants, VDI- Berichte 1703 Geothermische Stromerzeugung, ISBN 3-18-091703-2,

[3] A. Mlcak, Henry (2002), “Kalina Cycle Concepts for Low Temperature Geothermal”. Journal of Geothermal Resources Council Transaction vol. 26, pp 712 . Thank You to www.powereng.com for the support.

[4] Shah, Ramesh K. & Sekulić, Dusan P., Fundamental of Heat Exchanger Design, (Canada: John Wiley & Son, 2003)

[5] Cengel, Yunus A., & Boles, Michael A., Thermodynamic: an Engineering Approach, 2nd Ed. pp 411. (North America: McGraw-Hill., 1994).

[6] J. Ahrendts, Reference States, Energy, Vol. 5, (1980) 667-677.

[7] A. Mlcal, Henry (2001), “Design and Start-Up of the 2 MW Kalina Cycle® Orkuveita Húsavíkur Geothermal Power Plant in Iceland”. European Geotherma Energy Council : 2nd Business Seminar EGEC 2001

[8] A. Mlcal, Henry, et al., Notes from the North: a Report on the Debut Year of the 2 MW Kalina Cycle® Geothermal Power Plant in Húsavík, Iceland, USA, April 2002.

great blog 😀

yups thank you

Maul, bisa dijelasin dalam bahasa indonesia gag…??

thanks

ooh OK,, bisa di lakukan itu.. tenang saja siiipp

thanks…klo bisa gambarnya diperjelas lagi ok…

-bstrgds-

bisa tapi gambar akan melakukan link ke tempat file hosting lain, bukan dari wordpress langusng, karena wordpress tidak menyediakan penyimpanan kapasitas besar.

Wonderful website I will come back again soon.

Thank you,

and sorry for late reply, I have kindly thing to do

Your blog is so informative … ..I just bookmarked you….keep up the good work!!!!

Hey, I found your blog in a new directory of blogs. I dont know how your blog came up, must have been a typo, anyway cool blog, I bookmarked you. 🙂

surface encounters mi

Thanks Devin, you can visit again.

I am the kind of hombre who passions to seek unprecedented things. Presently I am fabricating my own solar panels. I’m making it all alone without the assistance of my men. I am using the internet as the only path to acheive that. I ran across a truly brilliant site which explains how to contruct pv panels and wind generators. The internet site explains all the steps needed for photovoltaic panel construction.

I’m not really sure bout how accurate the information given there is. If some guys over here who have experience with these things can have a see and give your feedback in the site it will be awesome and I’d highly appreciate it, cause I extremely love solar panel construction.

Thanks for reading this. You people rock.

umm… I am not

This is the best information I have found so far, thank you for this. We are professionals working on

Nice Blog

Boleh tau tentang turbin yang digunakannya??

lebih ke designnya

Thanks

ada ym ndak om?? Thank again

turbin yang digunakan memiliki thermal efficiency 90% namun untuk mechanical efficiency 70%.

mengenai design, semua itu disesuakan dgn fabrikasi..

Nice post..

skrg sy sdg melakukan tugas akhir mngenai siklus kalina.software yg sy gunakan Hysis. Mas melakukan validasi hasil perhitungan software pk apa ya??soalnya sy bingung mlakukan validasinya..

mkasih

terimakasih atas komennya,

karena pak Bobby pakai software yang berbeda dari yang saya pakai coba cari data ke perusahaan2 EPC yang pernah menangani proyek geothermal atau proyek power plant lainnya.

saya memperoleh data dari perusahaan tersebut dan itu sangat membantu dalam proses validasi.

jika bapak bisa download article ini di http://www.springerlink.com/content/kj7364p86j56804l/

mungkin akan membantu sekali dalam menulis tugas akhir anda

oh iya, saya sarankan Anda mengunjungi perpustakaan Fakultas Teknik Universitas Indonesia, diperpustakaan tersebut ada beberapa skripsi yang membahas energi dan exergi juga ada skripsi yang membahas kalina cycle.

boleh tau cycle tempo ny download di mana?

http://www.3me.tudelft.nl/live/pagina.jsp?id=8c53f82e-a500-41f1-971b-629e832bfbef&lang=en

sepertinya anda harus bayar

boleh share cycle tempo nya ga?

wah, maaf ga bisa saya share karena ber-lisence

kayaknya kenal nih, minimal inget mukanya laah

hahahahahah

hmmm

mas bisa bantuin saya ga tentang pengertian efisiensi exergi n energy ?

bingung ngebedain soalnya…so akhirnya jadi bingung juga menjelaskan result dari cycle temponya…hahahaha

sudah saya balas di email,, karena disini pebahasannya panjang

Salam,

Senang sekali saya bisa mendapatkan halaman webnya mas Maulana,

Saya seorang mahasiswa dari Jayapura-Papua, lg nyusun tugas akhir tentang exergy dan optimasi PLTU Jayapura. Saya sudah menghitung energy dan exergy berdasarkan referensi A. Bejan (Thermal Design).

Karena pembimbing menyarankan untuk menggunakan software, maka saya usahakan dan sudah mendapatkan software cycle-tempo v.5.

Setelah mempelajari buku petunjuk serta beberapa contoh yang ada, kemudian saya membuat gambar instalasi di cycle-tempo. Namun setelah berkali-kali saya input data pada semua apparatus maupun pipa, selalu saja error pada saat di’run’ dan yang bikin pusing jika terakhir tinggal 1 error.

Pada kesempatan ini bolehkah Mas Maulana Rifaldi membantu saya MENGINPUT DATA-DATA PADA SETIAP APPARATUS? jika berkenan akan saya kirim gambar instalasi serta data2 termodinamika PLTU (via email)?

Terima kasih.

halo Pither,

apa yang sudah dikerjakan oleh Pither saya pun pernah mengerjakannya dan mengalami berbagai error. Itu semua karena dulu saya hanya memahami sebatas menggunakan. namun kemudian saya mempelajari lebih lanjut petunjuk yang ada di buku manualnya. Cycle-Tempo terdiri dari beberapa persamaan dan dibuat dalam matrix.

saya senang bisa membantu, tapi pada minggu-minggu ini saya sedang menyusun thesis untuk S2 saya. kirim saya email mengenai data-data PLTU papua. jika Pither search di Google, pakai nama saya dan judul skripsi saya (terjemahkan judul page ini ke bahasa indonesia), maka skripsi saya bisa Pither download di perpustakaan online Universitas Indonesia.

Pither bisa berkreatifitas denga skripsi saya, lihat data yang saya tulis didalamnya, kemudian krim ke email saya berupa data PLTU papua

Bagaimana data saya apakah sudah pernah dibuka/dicoba dgn cycle-tempo?

Trims.

saya belum terima data anda.

coba kirim ke email saya

Adakah rumus PEC untuk Steam turbine?

maaf baru balas krena masuk musim dingin disini, kesehatan terganggung.

di Kalina Cycle, semua formula sudah ada didalam software, tinggal menentukan jenis Turbin. oleh karena itu sy pernah simulasikan cycle anda. sy kesulitan menemukan tipe turbine yang dipakai. coba anda tanyakan ke pihak pltu papua.

Bapak Maulana Rifaldi,

Saya mau tanya lagi, exergy destruction terbesar dan terkecil di komponen mana pada sistem PLTU? Sistem yang saya analisa terdiri atas boiler, turbin, kondensor, heater, deaerator dan pompa. Ada referensi yang saya dapat dari internet berupa diagram Grassman dimana exergy destruksi terbesar pada boiler kemudian turbin dan terkecil pada kondensor, sedangkan pada perhitungan saya justru sebaliknya.

Terima kasih informasinya.

Pak, bagaimana membuat input bahan bakar untuk boiler sehingga yang variabel adalah output generator. Kalau pakai Production Function, output daya (MW) adalah tetap, misal 10 MW. Nah gimana caranya supaya daya (MW) yg varibael dengan merubah parameter lain. thanks.

coba ubah pressure input ke turbin atau steam mass flow ke turbin.

-regard-

Mohon bantuannya pak Maulana, saya ingin pembuatan pemodelan heat balance dengan cycle tempo untuk PLTU. Saya sudah mencoba untuk membangun permodelannya tapi saat di running hasilnya error.

Bisa minta email dan no telpon yang bisa dihubungi pak.

Assalamu alaikum…

perkenalkan saya mahasiswa dari makassar mas…

saya sangat senang bisa mengunjungi halaman webnya mas Maulana,

saya mhon bimbingan mas, saya sdang mngerjakan TA saya dngan mnggunakan Cycle tempo mengenai pengaruh variasi ekstraski turbin terhadap efisiensi termal sistem…

Setelah mempelajari buku petunjuk serta beberapa contoh yang ada, kemudian saya membuat gambar instalasi di cycle-tempo. Namun setelah berkali-kali saya input data pada semua apparatus maupun pipa, selalu saja error pada saat di’run’ dan yang bikin pusing jika terakhir tinggal 1 error.

Pada kesempatan ini bolehkah Mas Maulana Rifaldi membantu saya MENGINPUT DATA-DATA PADA SETIAP APPARATUS? jika berkenan akan saya kirim gambar instalasi serta data2 termodinamika PLTU (via email)?

Terima kasih.

Wassalam…

wa’alaykumsalam wrwb.

cycle-Tempo versi berapa yang digunakan?

cek data yang dipunyai sudah lengkap dari Pembangkit Listrik yang ditinjau. gunakan data Realistis dan bukan data secondary. untuk input data baiknya dilakukan sendiri karena akan terlihat data apa saja yang kurang.

selamat berjuang

terima kasih sblumnya atas blasan dri mas maulana…

cycle tempo yng saya gunakan adalah cycle tempo 5.0…

data yang saya masukan sdah bberapa kali saya cek mngikuti manual booknya…

tpi hasilnya masih ttap sama…

pada saat di run muncul 1 error dan 1 warning…

1.105 WARNING —> GENERATOR

FOR GENERATOR NUMBER 1, ETAGEN IS SPECIFIED, SO ALL OTHER

DATA WILL BE IGNORED !

Calculating generator data …..

Eliminating mass equation …..

2.13 ERROR —> TOTAL NUMBER OF EQUATIONS ( 24) TO CALCULATE THE MASS FLOWS IN THE SYSTEM MUST EQUAL THE NUMBER OF PIPES ( 25).

HE NUMBER OF EQUATIONS IS INCREASED WITH 1 BY SPECIFYING:

* PARAMETER EEQCOD 1 IN STEAD OF 2 (APPARATUS TYPES “CONDENSER”, “HEAT EXCHANGER”, “NODE”, “COMBUSTOR”,”REFORMER”, “FUEL CELL”, “MOISTURE SEPARATOR” AND “GASIFIER”)

* PARAMETER DELM FOR A MASS SOURCE OR SINK (A BEGIN OR AN END OF AN OPEN SYSTEM, RESPECTIVELY)

* A PRODUCTION FUNCTION FOR AN APPARATUS OR A GROUP OF APPARATUSES A SURPLUS POWER FOR A DRIVE TRAIN WITH ONE OR MORE TURBINES AND ONE OR MORE PUMPS/COMPRESSORS

* PARAMETER LAMBDA FOR A “COMBUSTOR” (WITH EEQCOD=2)

* PARAMETER UOX FOR A “FUEL CELL”

* PARAMETER POWER FOR A “FUEL CELL”

* PARAMETER OFRATI FOR A “GASIFIER”

* PARAMETER SFRATI FOR A “REFORMER” OR A “GASIFIER”

THESE CHANGES DO NOT AFFECT THE SCHEME. CHANGES INCREASING THE NUMBER OF EQUATIONS WITH 1 BUT ALSO AFFECTING THE SCHEME ARE:

* REPLACING A “NODE” (WITH EEQCOD=2) BY A “VALVE” (FOR WHICH ALWAYS A MASS FLOW MUST BE SPECIFIED)

* REPLACING A “HEAT EXCHANGER” (WITH EEQCOD=2) BY A “FLASHED HEATER” (WHICH WILL ALWAYS CALCULATE ONE OF THE MASS FLOWS IN THE CONNECTED PIPES)

PLEASE REFER TO THE MANUAL TO SEE THE NUMBER OF EQUATIONS

THAT A CERTAIN APPARATUS TYPE WILL SUPPLY TO THE SYSTEM

MATRIX FOR CALCULATING THE MASS FLOWS IN THE SYSTEM.

Execution inhibited due to error count …..

Number of errors: 1

mhon pencerhannya mas…

trima kasih…

untuk data Generator coba input efficiency saja. tidak perlu menginput berapa MegaWatt yang diinginkan.

routing lagi pipanya dan equipmennya. cek apakah di equipment tersebut diperlukan perhitungan mass equation.

lanjutkan.

sebelum akhir penyerahan skripsi.

iya mas…

batas akhir ujian skripsi tinggal 3 minggu lgi…

saya sdah cek ETAGEN nya mas…

warning generator sdah hilang…

yang tersisa tinggal error 1 lgi…

dari error itu menujukkan apparatur no. 24 dan 25…

dri model saya itu adalah pipa steam kondensat dari HPH1 ke HPH 2, dan pipa dari HPH2 ke LPH1…

perhitunggan mass equation bagaiaman maksudnya mas???

dri pesan error itu jika diartikan, katanya untuk total jumlah persamaan untuk menghitung laju aliran massa dalam sistem harus sama dengan jumlah pipa…

saya masih bingung dengan pesan tersebut…

mhon bantuannya mas…

dari pesan error tersebut, apakah Production Function dimasukkan nilainya?

jika iya, maka perlu diatur kode EEQCOD yang mengatur mass equation pilih kode 1 atau 2 pada tiap equipment. hilangkan 1 mass equation di salah satu equipment/apparatus di siklus yang dibuat.

maksud dri production function bgaimana mas???

EEQCOD = 1, untuk apparat Kondensor…

selanjtunya untuk tiap flash heater itu SATCOD = 0…

atau apa saya bisa mngrimkan ke email mas file model saya mas??? untuk langsung diperiksa saja…

mhon bantuannya mas…

alhamdulillah stlah mengotak atik nilai input, maslah sblumnya sdah terpecahkan mas…

tpi muncul masalah baru…

pada pesan erro kli ini muncul…

Calculating generator data …..

Eliminating mass equation …..

Set mediumtype in all pipes …..

Cycle-Tempo iteration 0:

————————–

Calculating mass fractions …..

Calculating thermodynamic properties …..

4.01 ERROR –> TOO LESS DATA AVAILABLE FOR COMPUTING THE THERMODYNAMIC

PROPERTIES OF ALL LINKS.

THE PROGRAMS GIVES A HIGHER PRIORITY TO PRESSURES, SO CHECK

THE PRESSURES FIRST !

PIPE APPARATUS PRESSURE TEMPERATURE ENTHALPY

NO NO [bar] [°C] [kJ/kg]

1 1 88.00 537.70 3483.62

2 88.00 537.70 3483.62

2 2 0.08200 41.98 2236.76

3 0.08200 41.98 2236.76

3 3 0.08200 41.98 175.81

4 0.08200 41.98 175.81

4 4 1.500 41.99 176.00

5 1.500 41.99 176.00

5 5 1.500 42.81 179.40

6 1.500 42.81 179.40

6 6 1.500 86.93 364.13

7 1.500 86.93 364.13

7 7 1.500 101.78 426.66

14 1.500 101.78 426.66

8 14 1.500 —- ? —- —- ? —-

8 1.500 —- ? —- —- ? —-

9 8 1.500 111.35 467.08

9 1.500 111.35 467.08

10 9 149.8 113.72 487.83

10 149.8 113.72 487.83

11 10 149.8 129.97 556.28

11 149.8 129.97 556.28

12 2 13.00 282.49 3005.14

11 13.00 282.49 3005.14

13 2 2.700 129.97 2711.87

10 2.700 129.97 2711.87

14 2 1.500 111.35 2619.74

8 1.500 111.35 2619.74

15 2 1.200 104.78 2586.24

7 1.200 104.78 2586.24

16 2 0.7000 89.93 2508.45

6 0.7000 89.93 2508.45

17 2 0.10000 45.81 2259.68

5 0.10000 45.81 2259.68

18 3 3.000 58.80 246.37

12 2.000 58.82 246.37

19 15 1.000 12.00 50.51

13 1.000 12.00 50.51

20 13 3.000 12.02 50.77

3 3.000 12.02 50.77

21 5 0.10000 45.81 191.81

3 0.08200 41.98 191.81

22 6 0.7000 47.81 200.22

5 0.10000 45.81 200.22

23 7 1.200 91.93 385.13

6 0.7000 89.93 385.13

24 10 2.700 120.72 506.90

8 1.500 111.35 506.90

25 11 13.00 136.97 576.83

10 2.700 129.97 576.83

26 11 149.8 191.61 821.16

1 149.8 191.61 821.16

Execution inhibited due to error count …..

Number of errors: 1

mohon bantuannya mas…

Nah, sekarang coba perhatikan pipa no.8, pada equipment yang terkoneksi no.14 dan no.1 data yang belum lengkap itu pressure, temperature dan kalor.

coba input data disana

maslah sblumnya sdah terpecahkan mas…

tpi muncul masalah baru…

pada pesan erro kli ini muncul…

Calculating generator data …..

Eliminating mass equation …..

Set mediumtype in all pipes …..

Cycle-Tempo iteration 0:

————————–

Calculating mass fractions …..

Calculating thermodynamic properties …..

4.01 ERROR –> TOO LESS DATA AVAILABLE FOR COMPUTING THE THERMODYNAMIC

PROPERTIES OF ALL LINKS.

THE PROGRAMS GIVES A HIGHER PRIORITY TO PRESSURES, SO CHECK

THE PRESSURES FIRST !

PIPE APPARATUS PRESSURE TEMPERATURE ENTHALPY

NO NO [bar] [°C] [kJ/kg]

1 1 88.00 537.70 3483.62

2 88.00 537.70 3483.62

2 2 0.08200 41.98 2236.76

3 0.08200 41.98 2236.76

3 3 0.08200 41.98 175.81

4 0.08200 41.98 175.81

4 4 13.60 42.13 177.63

5 13.60 42.13 177.63

5 5 13.60 42.81 180.46

6 1.500 43.06 180.46

6 6 1.500 86.93 364.13

7 1.500 86.93 364.13

7 7 1.500 101.78 426.66

8 1.500 101.78 426.66

8 8 1.500 111.35 467.08

9 1.500 111.35 467.08

9 9 149.8 113.72 487.83

10 149.8 113.72 487.83

10 10 149.8 129.97 556.28

11 88.00 130.97 556.28

11 11 88.00 191.61 818.21

1 88.00 191.61 818.21

12 2 13.00 282.49 3005.14

11 13.00 282.49 3005.14

13 2 2.700 129.97 2711.87

10 2.700 129.97 2711.87

14 2 1.500 111.35 2619.74

16 1.500 111.35 2619.74

15 2 1.200 104.78 2586.24

7 1.200 104.78 2586.24

16 2 0.7000 89.93 2508.45

6 0.7000 89.93 2508.45

17 2 0.10000 45.81 2259.68

5 0.10000 45.81 2259.68

18 3 3.000 58.80 246.37

12 2.000 58.82 246.37

19 15 1.000 12.00 50.51

13 1.000 12.00 50.51

20 13 3.000 12.02 50.77

3 3.000 12.02 50.77

21 5 0.10000 45.81 191.81

3 0.08200 41.98 191.81

22 6 0.7000 48.06 201.29

5 0.10000 45.81 201.29

23 7 1.200 91.93 385.13

6 0.7000 89.93 385.13

24 10 2.700 120.72 506.90

8 1.500 111.35 506.90

25 11 13.00 137.97 581.10

10 2.700 129.97 581.10

27 16 1.500 —- ? —- —- ? —-

8 1.500 —- ? —- —- ? —-

Execution inhibited due to error count …..

Number of errors: 1

mhon bantuannya mas….

coba input data pressure pada equipment 16 dan 1. tapi dengan data real

i need help in using cycle tempo. whenever i try any tutorial i always get error. Please help me to just run a single program. any help will be greatly appreciated. Please contact on bilalskp99@gmail.com.

Assalamu alaikum mas Maulana…

mau nanya lagi ni mas bagai mana itu kalau simulasinya tidak bisa keluar daya mekanik sama massa flownya…??? apanya yang dirubah….???

mohon bantuannya mas…

coba input efficiency mechanical nya

sudah dikasih mas tapi masi tidak bisa keluar datanya, apanya lagi yg dirubah..???

Sir,

I need the cost to build a Kalina cycle generator which will be coupled to a plasma gasifier using msw as feedstock. I came acroos your blog and would like to know if you can help me. The gasifier will process 1000 tons of msw per day as a baseline. If you cannot help me can you please direct me to someone who can.

Sincerely,

M.W. Sullivan

Assalamu’alaykum, maaf pa Maulana Rifaldi apakah saya minta tutorial cycle tempo dalam bahasa indonesia ga?? atau cari bukunya dimana??

terima Kasih pa

Saya tidak punya yang berbahasa Indonesia. Tutorial ada dalam paket software pak

Assalamualaikum, mas..

alhamdulillah….saya sangat senang bisa mendapatkan halaman webnya, mas..

perkenalkan saya seorang mahasiswi asal Makassar, mas…

begini, mas..saya mhon bimbingan mas maulana..sekarang saya sedang mengerjakan Tugas Akhir saya dengan mnggunakan Cycle tempo yang berjudul ANALISIS EKSERGI PADA PLTU PT. MKS TENE KAPASITAS 6 MW DENGAN MENGGUNAKAN CYCLE TEMPO

Saya telah mempelajari buku petunjuk dan membuat permodelan sistem PLTU PT. Mks Tene sesuai data di cycle-tempo. Simulasinya alhamdulillah sudah bisa di ‘run’, mas. Namun yang bikin saya pusing nilai hasil SIMULASI ELECTRICAL POWER, MECHANICAL POWER tidak sesuai harapan (nilainya minus), mas. Kemudian nilai hasil simulasi untuk EXERGY LOSS untuk semua komponennya KOSONG, MAS.:(

saya mohon bantuannya, mas Maulana…

jika mas Maulana berkenan membantu saya, saya akan segera mengirim file simulasi TA saya via email untuk dikoreksi, mas..

sekali lagi, saya sangat mohon bantuannya mas Maulana…

sebelumnya terima kasih, mas..

Wassalam..

waalaykumsalamwrwb.

Silahkan boleh kirim. Saya coba luangkan waktu.

Jika lulus nanti jangan lupa bantu adik adiknya yg masih kuliah.

terima kasih, mas..

iya, mas..saya siap bantu adik-adik..

Could you please reply to questions or when you leave statements on new findings in English for I do not speak Indian, much appreciated.

Assalamualaikum, mas..

terima kasih, mas..

saya baru saja sudah kirim filenya ke emailnya, mas..

Coba cek apakah sdh terkirim. Di email saya tdk ada. Atau kirim kembali

Hi Maulana. I’m have working trouble in cycle tempo. I’m working on a Brayton cycle. Apparently the problem is in the EEQCOD or turbine combustor. and says the number of equations (8) to calculate the mass flows in the systems must equal the number of pipes (5). Please, help me! Thank you so much!

Hi Francia, sorry for very long reply. I’ve been busy at my job this year. I hope you have found the answere.

Semat siang pak

Saya ada kendala pada input data cycle tempo.

Pada apparatus feed water heater Katanya -temperature at primary inlet too high.

-Low terminal temperature diff. too high

-Pressure at secundary outlet too low.

Padahal sudah saya masukan Sesuai heat balance.

Mohon bantuan nya pak.

Periksa kembali parameter inputnya, efisiensi mekanikal dan kode inputnya.

Sebenarnya pertimbangan pemilihan separator apa ya gan ? Kadang ada yang pake dan ga pake.

separator berfungsi memisahkan fluida fasa liquid (condensed/saturated) dengan fasa gas